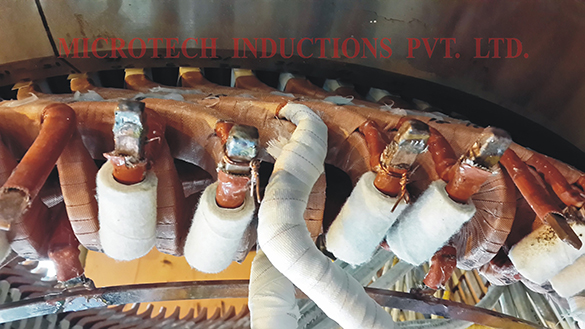

Microtech Inductions Pvt. Ltd. make Induction Heating, Brazing Machine with Hand held Transformer is a handy tool for heating and brazing applications. The Hand Held Transformer (HHT) is attached to the machine using a flexible cable. HHT can be used just like a welding torch with ease. The main applications are brazing of stator winding in motor, generators, connecting leads of transformer, removal of bonded rubber heating pads, rubber glued pads on metal surface.

- Brazing of generator stator windings.

- End ring brazing of rotors

- Copper bus bars brazing of transformers

- Copper parts for compressors.

- Brazing of condenser coil.

- Submersible pump rotors.

- Ring cable lugs.

- Aluminum component joints.

- Soldering of brass components.

- Steel components joints.

- Brazing of storage water heater Elements.

- Diamond tipped cutting tools.

- Carbide tipping of cutting tools.

- Optical Frame Brazing.

- Fuel pipe Brazing.

- Vacuum brazing of critical components.

- Brazing stainless steel orthodontic parts.

- Brazing of stainless steel to Brass.

- Rocker Pins.

- Hydraulic Hose.

| POWER RANGE | 1-5KW | 05-15KW. | 15-50KW | 50 -200KW |

| FREQUENCY RANGE | 15-400kHz | 15-100 kHz | 15-30kHz | 15 – 30kHz |

| ADAPTATION TO CHANGE LOAD CHARECTERISTICS | YES | YES | YES | YES |

| POWER CONTROL | AUTO | AUTO | AUTO | AUTO |

| LOAD SENSED SELF TUNING | YES | YES | YES | YES |

| SIZE (mm) | W-170 B-495 H-350 |

W-530 B-640 H-1110 |

W-620 B-725 H-1370 |

W-1000 B-1090 H-1675 |

| INPUT POWER RANGE | SINGLE PHASE 230V/50Hz. |

THREE PHASE 440V/50Hz |

THREE PHASE 440V/50Hz |

THREE PHASE 440V/50Hz |

will be updated soon

Videos

More Links

will be updated soon