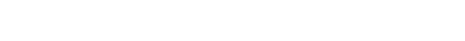

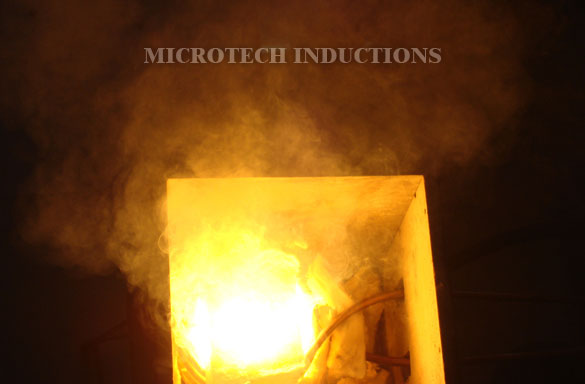

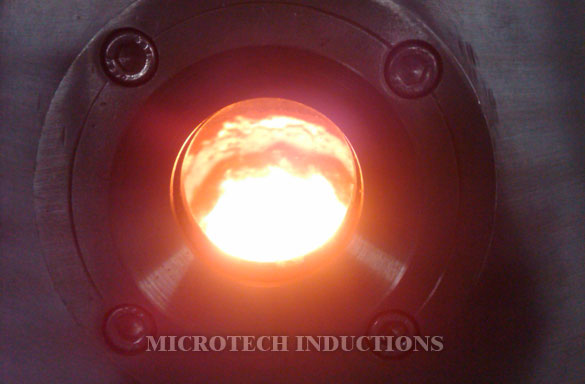

Induction melting is the process to melt the ferrous and non-ferrous metals for forming applications, tools & component casting and percious metal melting etc.

Microtech Induction Melting Furnace provides very efficient & time saving melting of metals for various applications

- Gold Melting.

- Silver Melting.

- Levitation Melting Systems in microgravity of space.

- Vacuum Induction Melting.

- Platinum Melting.

- Very high Temperature Induction Melting.

- Crystal Growing.

- Alloy Melting.

- Aluminium Foundry.

- Steel Foundry.

- High Temperature ceramic melting furnace.

| POWER RANGE | 1-5KW | 05-15KW. | 15-50KW | 50 -200KW |

| FREQUENCY RANGE | 5-600kHz | 01-400 kHz | 01-30kHz | 01 – 30kHz |

| ADAPTATION TO CHANGE LOAD CHARECTERISTICS | YES | YES | YES | YES |

| POWER CONTROL | MANUAL | AUTO | AUTO | AUTO |

| LOAD SENSED SELF TUNING | YES | YES | YES | YES |

| SIZE (mm) | W-225 B-500 H-430 |

W-530 B-640 H-1110 |

W-620 B-725 H-1370 |

W-1000 B-1090 H-1675 |

| INPUT POWER RANGE | SINGLE PHASE 230V/50Hz. |

THREE PHASE 230V/50Hz |

THREE PHASE 440V/50Hz |

THREE PHASE 440V/50Hz |

In our Endeavour to make better products, Microtech Induction Pvt. Ltd. reserves the right to change any specifications at any moment and without prior notice, to the models (including programming) and their accessories.

will be updated soon

Videos

More Links

will be updated soon